Don't be surprised if you see pills with unusual shapes in the near future. They may look bizarre at first glance, but they can release drugs in the body in a controlled manner. Thanks to a combination of advanced computational methods and 3D printing, objects are created that dissolve in liquids in a specific way.

A group of computer scientists from the Max Planck Institute for Computer Science in Saarbrücken and the University of California at Davis have developed a method in which the shape of the object alone is decisive for a time-controlled release. This will have important implications for the pharmaceutical industry, which has recently focused heavily on 3D printing.

Monitoring the drug level in the patient is an important part of medication. In an intravenous infusion, the concentration in the blood is determined by the drip rate multiplied by the proportion of the drug in the infusion solution. A constant drug level can be achieved by first administering a high dose and then maintaining it through smaller doses. With oral administration, this system is much more difficult to ensure. One idea would be to use multicomponent and multimaterial structures with different drug concentrations at different sites, which is difficult to manufacture. On the other hand, with the great advances in 3D printing and its unbeatable capabilities to create complex shapes, the production of free-form drugs with a constant distribution of the biochemical agent in the carrier material is currently a viable option. For such drugs, the release depends solely on the geometric shape, which is easier to ensure and control.

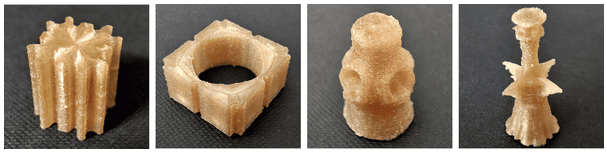

The project, led by Dr. Vahid Babaei (MPI of Computer Science) and Prof. Julian Panetta (UC Davis), will produce 3D objects that dissolve in a desired function of time, releasing their contents in a controlled manner. Through a clever combination of mathematical modeling, experimental setup and 3D printing, the team can 3D print shapes that release a timed amount of drug as they dissolve. In this way, predetermined drug concentrations can be set during oral administration.

Since no external influence is possible after ingestion in the digestive tract, the desired time-dependent drug release must be generated by the shape (active surface that dissolves) of the test specimen. With some effort, the time-dependent release can be calculated from a given geometric shape. For a sphere, for example, it is strictly proportional to the decreasing sphere surface area. The research team proposes a forward simulation based on the geometric intuition that objects are resolved layer by layer. However, practitioners are usually interested in first defining a desired release and then finding a shape that dissolves according to that release profile. Even with this efficient forward simulation, reverse engineering to find the appropriate three-dimensional shape for a desired drug regime presents significant difficulties.

This is where topology optimization (TO) comes in: forward simulations are inverted to find a shape that exhibits a specific property. Originally developed for mechanical components, TO has since found a wide range of applications. The team is the first to propose an inverse design strategy to find the shape from release behavior based on topology optimization. The resolution is validated with experiments: The measured release curves are very close to the desired values.

The pills are produced using a filament 3D printer, and the resolution of the objects is evaluated using a camera system. The measured release curves thereby largely match the desired values. In addition to its application in pharmaceuticals, the inverse design method can also be used to manufacture other products such as catalyst bodies or fertilizers. It also allows the manufacturing constraints of different manufacturing systems to be taken into account.

In this method of pill making, it is necessary to make a separate pill for each dosage in order to achieve the desired effect at the right time. Cutting a pill in half is not possible. The development of pills with targeted drug release using 3D printing and mathematical calculations opens up new possibilities for the medicine of the future. It enables more precise control of drug action in the body and opens up potential for further applications in various industries.

Batterman Consulting Basel AG

Executive Search,

Byfangweg 1a, CH-4051 Basel

T +41 58 680 55 55

basel@batterman.ch